Manual Tip Lifts

Overview

Manual tip lifts are an economical alternative to pneumatic or electric lifting equipment. They are primarily used for tilting rolls from a horizontal to vertical position and for vertical roll transportation. Unlike pneumatic or electric lifting equipment, manual tip lifts do not require air pressure or electricity to operate. Tilt-Lock offers manual tip lifts that can fit a variety of core sizes and have a maximum load capacity of up to 2,000 pounds.

How does it work

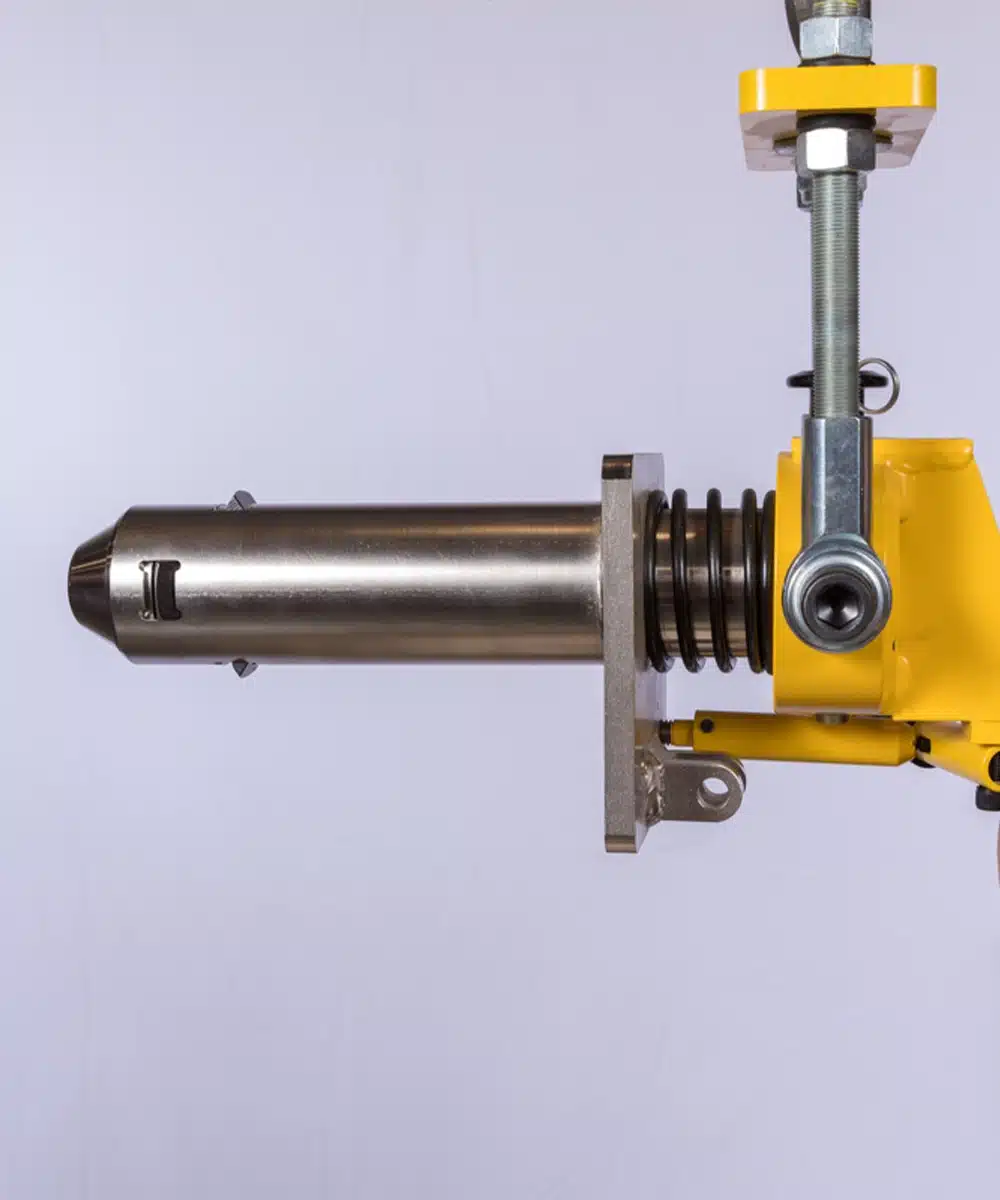

Manual tip lifts are remarkably simple to use: The operator begins by inserting the lifter’s cylindrical metal probe into the core of the roll. The probe is equipped with mechanical teeth that grasp the roll and hold it firmly in place.

Next, the operator uses the button on the tip lift’s handle to tilt the roll on the hoist, which causes it to rotate 90 degrees. As a safety precaution, the tooth release will not disengage from the probe while the roll is in the air.

To remove the lifter, the operator lowers the roll to the ground, squeezes the handles together and lifts up on the hoist. The weight of the roll must be supported by a stationary surface in order to disengage the roll. The manual tip lift does not lock in the horizontal position, which differentiates it from our other roll handling equipment offerings.

Capabilities & Benefits

With a manual tip lift from Tilt-Lock, your warehouse team will be able to lift and transport rolls of material weighing up to 2,000 pounds with ease, minimizing the risk of injuries and product damage while also increasing your business’s productivity and profitability.

Injury Reduction

Although they’re called “manual” tip lifts, these easy-to-use, fingertip-controlled devices reduce the amount of physical effort required. Your workers will experience less fatigue and fewer injuries that could keep them off the job.

Efficiency

Your team will be able to quickly and easily pick up a variety of roll sizes with one tip lift, which can boost your work efficiency and significantly reduce your company’s equipment costs. Our manual tip lifts are also furnished with a quick release pin to ensure a fast, easy changing of probes.

Damage Reduction

Manual tip lifts offer a built-in failsafe that prevents operators from accidentally dropping the roll and damaging the material.

Product Specs

At Tilt-Lock, we specialize in producing high-quality material handling equipment that’s engineered with the customer in mind. Our products combine simplicity and functionality to deliver the best long-term results. We offer manual tip lifts that can handle a variety of core sizes to meet the roll lifting needs of every work environment.

Uses & Applications

Our manual roll lifters can meet the needs of virtually any work environment that involves lifting, moving, and loading big, bulky rolls of material such as paper, film or foil. Manual tip lifts are an extremely popular lifting solution for a huge variety of industries, including printing, food processing and pharmaceuticals.

Dimensions

The dimensions of a Tilt-Lock manual tip lift are 11” (horizontal) x 25.5” (vertical).

Specifications

- Minimum 3” wide roll required for proper probe functionality.

- Tip lifts can be supplied with a quick release pin for interchanging probes to accommodate different core diameters as needed.

- Some operators may have difficulty squeezing the V-shaped handle required to retract the teeth. Contact us to learn more about our available pneumatic tooth release package.

Request a Quote

Ready to upgrade your work processes with a manual tip lift solution from the experts at Tilt-Lock? Contact us today to request a quote for your facility’s needs.