Roll Overs

Roll Overs

Overview

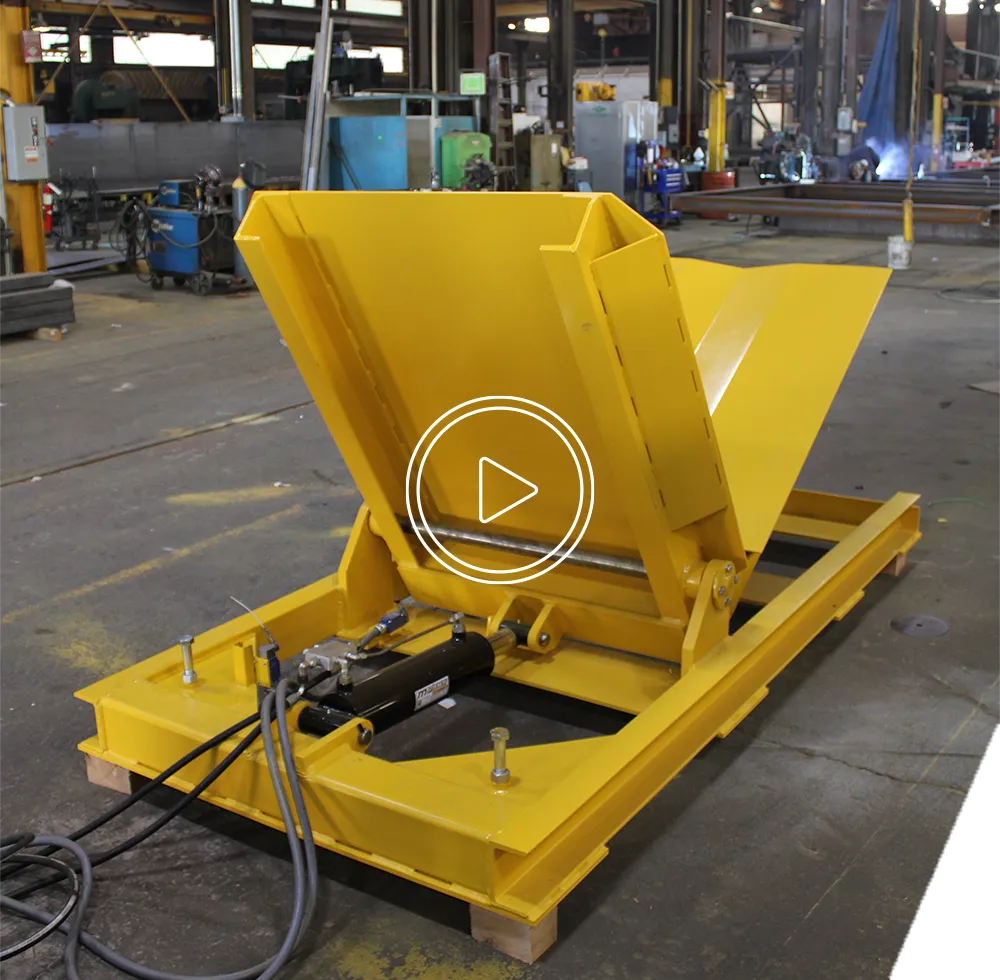

Tilt-Lock Roll Overs offer a unique design with a rugged construction to assure quiet, trouble-free operation and performance. These units are designed to turn one or multiple rolls at a time for both loading or unloading onto a pallet with ease. Every Tilt-Lock Roll Over is custom built to your unique specifications, allowing you to implement a solution that is tailored to your environment and application.

How does it work

The Roll Over operator controls the hydraulic tilt function from a push button station. Tilt-Lock Roll Over are self- supporting, meaning they do not have to be fastened to the floor and are therefore a portable roll-tilting solution.

For unwind applications, a fork truck delivers the palleted roll to the Roll Over table. At the push of a button, the roll is gently pivoted to a horizontal position. A ramp can be used to roll the material to a shafting position.

Capabilities & Benefits

If you’re looking for a better, safer way to handle your materials, look to the Tilt-Lock Roll Over. Our Roll Overs offer a smooth, low-maintenance solution to your material tilting needs.

INJURY REDUCTION

TIlt-Lock designs all equipment with safety as a top priority. When you incorporate a Roll Over in your daily operations, you’ll experience fewer injuries in your workplace, which will reduce employee absences and help minimize costly workers’ compensation claims.

EFFICIENCY

Our equipment allows your team to work faster and more efficiently, so you can increase your output without adding staff to the payroll. Our Roll Overs are simple to operate and do not require a lengthy learning curve, minimizing unproductive downtime.

DAMAGE REDUCTION

How much money does your company lose each year because of mishandled, damaged materials? Our roll tilting equipment reduces the likelihood of dropped rolls, which will have a positive impact on your profitability.

Product Specs

Our Roll Overs are remarkably low-maintenance, requiring only routine checking of the hydraulic system. Optional equipment available includes pallet holders, ramps, and notched tables for loading and unloading with c-hooks.

Uses & Applications

Roll Overs are suitable for applications in which a tip-lift is not an appropriate solution for lifting and tilting material rolls. The self-supporting design of our Roll Overs offer exceptional stability, mobility, and efficiency while effortlessly handling rolls weighing up to 6,000 lbs.

Dimensions

All Tilt-Lock Roll Overs are custom-made to our clients’ unique requirements. Your Roll Over solution will have dimensions specific to your space, application, and other needs.

Specifications

Due to the custom nature of our Roll Over solutions, your Roll Over’s capacity, rotation time and other specifications will vary. Listed below are our standard capabilities and options.

- Maximum Capacity: 6,000 lbs., depending on face width.

- Rotation Time: 15 to 20 seconds, depending on pump voltage.

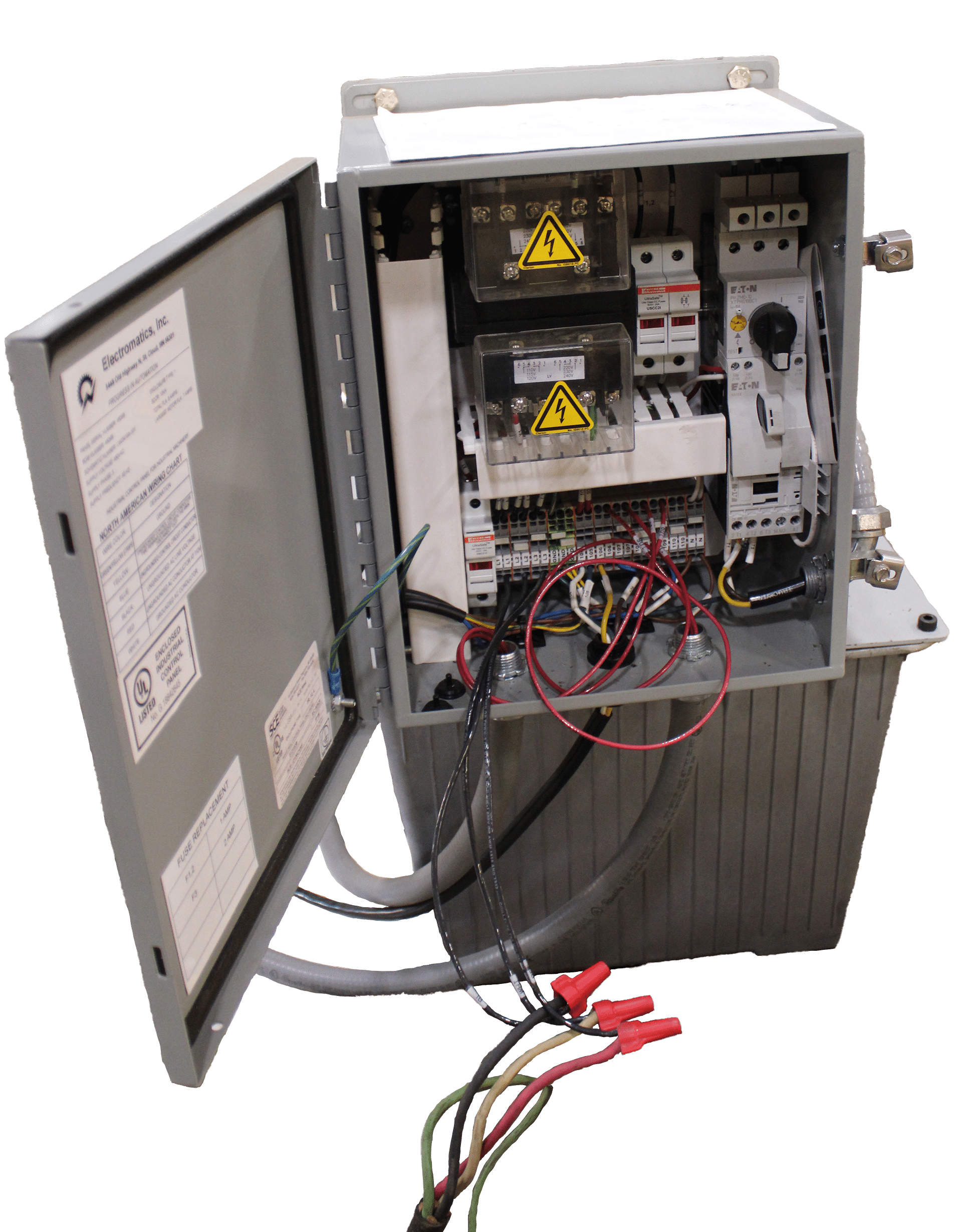

- Power: 460/230 volt 3 phase. Other voltages available.

- Control Voltage: 110 volts for operator safety.

- Control: Two-button station with magnetic disconnect with 10 ft of cable.

- Hydraulic system for quiet, efficient operation and better workflow.

- Counterbalance valves hold the table-tilting cylinder in case of hydraulic system or hose failure.

- Heavy-duty industrial grade hydraulic power units.

- All bearings are sealed and pre-lubricated.

Request a Quote

Ready to upgrade your work processes with a Roll Over solution from the experts at Tilt-Lock? Contact us today to request a quote for your facility’s needs.